Our company has moved to a new facility and continues production with three production lines. At our new facility, we have three fully automatic galvanizing lines with a production capacity of 30 wires per line and 8,000 tons per month. The second and third production lines provide homogeneous annealing with the advantage of the fluidized bed system and the aluminum quartz sand side of the furnace that contacts all the surfaces of the wires. This kind of oven we use has the latest technology and all the equipment is imported from Canada.

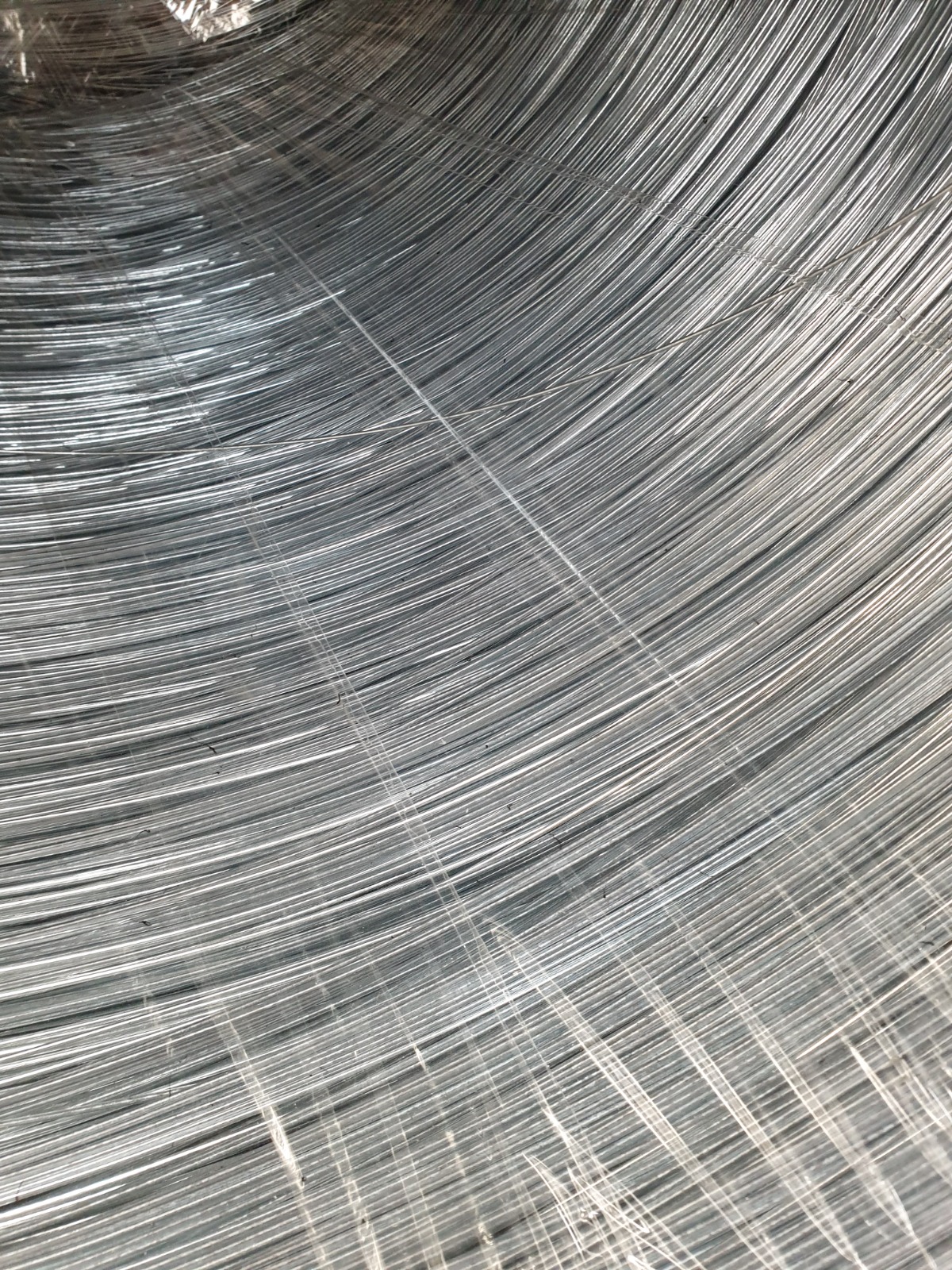

Our production lines can produce commercial coated and coated wires from 0.80 mm to 8.00 mm thick. Commercial coated wires are produced with a pad wiping system with a high quality n coating and surface of the wires. Hgh-Zinc coated wires are produced with a nitrogen wiping system. Production with low or medium carbon level, which is in international standards, is available in our production. Our wires are produced with 38-48-50 mm inner diameter and 70-80-95 mm outer diameter rosette cooling system. Column weights can vary between 350 kg and 2000 kg.